We Drive Production Efficiency

Smart Digital Solutions for Modern Industry

Driven by operational intelligence and industrial innovation, we empower manufacturing brands to scale throughput, optimize workflows.

Our Strategy

Reinventing Manufacturing Growth Through Digital Precision

We collaborate with manufacturers, industrial suppliers, and B2B producers to create data-driven marketing systems that amplify visibility, streamline lead generation, and accelerate business growth. Our strategies merge industrial expertise with cutting-edge digital tools — from SEO and PPC to automation and analytics — helping manufacturing brands connect with decision-makers, distributors, and buyers across digital channels. We engineer campaigns designed to boost inbound inquiries, enhance brand authority, and drive measurable production value.

Industrial Leads Generated

Manufacturing Campaigns Executed

Global Supplier Networks Scaled Digitally

Key Domains

Smart Manufacturing, Smarter Marketing

We focus on modernizing how manufacturers engage buyers, distributors, and engineers through powerful, tech-led digital strategies. Our goal is to build visibility, credibility, and long-term client relationships.

Trust

Build reputation through consistent, verified, and credible content.

Lead Generation

Attract decision-makers using SEO, PPC, and targeting.

Visibility

Boost online presence with keyword-optimized product listings.

Efficiency

Streamline workflows through automation, analytics, and insights.

Notable Benefits

Driving Industrial Transformation with Digital Impact

We bridge manufacturing expertise with data-driven marketing to ensure your brand thrives in an evolving digital supply chain.

Targeted B2B Marketing

Reach engineers, plant managers, and procurement heads through hyper-personalized outreach.

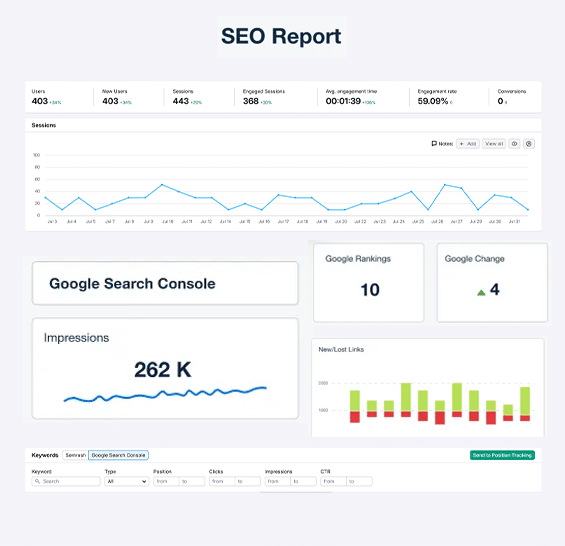

Performance Analytics

Track every campaign with real-time metrics that connect marketing impact to production ROI.

Automation Integration

Adopt CRM, email, and workflow automation to nurture leads efficiently across sales cycles.

Omnichannel Presence

Deliver consistent branding across websites, marketplaces, and industry networks.

Scalable Infrastructure

Build systems ready for product expansion, multi-location manufacturing, and global distribution.

Content-Driven Credibility

Publish expert blogs, case studies, and whitepapers that establish technical thought leadership.

Hands-On Collaboration

Align marketing strategies with plant operations.

Performance Impact

Boost brand visibility and qualified B2B leads.

Scalable Plant Systems

Promote smart manufacturing through digital outreach.

Operation Analytics

Use data-driven insights to improve overall market reach.

Execution Framework

Streamlined Phases for Manufacturing Success

Our structured approach ensures your brand’s digital transformation is efficient, scalable, and performance-focused.

01. Market Assessment

Analyze industry trends, competitor performance, and buyer behavior to define clear digital opportunities.

02. Strategy Design

Design marketing blueprints that align with your production capacity, distribution network, and audience.

03. Campaign Launch

Deploy targeted campaigns across SEO, paid media, and LinkedIn to maximize qualified inquiries.

04. Consistent tuning

Monitor engagement, refine messaging, and enhance conversion funnels through data insights.

Manufacturing Tech Stack

Essential Tools Powering Industrial Marketing

Empower your manufacturing business with automation, analytics, and marketing platforms that enhance productivity, lead tracking, and ROI. We integrate CRMs, ad systems, and digital dashboards for seamless operations and measurable outcomes.

Let’s build your digital future

Transform Rankings with Next-Gen SEO

Speak with a strategist to design a customized, scalable SEO roadmap for your business. Our advanced SEO intelligence to outrank the competition.

Manufacturing Marketing Case Studies

Real Results for Manufacturing Brands

Explore how we’ve helped manufacturers and industrial suppliers strengthen market visibility, streamline lead generation, and expand globally through targeted digital marketing.

SteelSync Industries

ProMach Systems

GearTech Global

AeroFab Solutions

Voices That Build Success

What Our Clients Say

Explore how manufacturers across automotive, electronics, and consumer goods achieved operational excellence with our digital enablement solutions.

Smart Answers Delivered

Find Answers To Your Most Common Questions

It generates high-value B2B leads, increases visibility, and builds credibility across industrial markets.

Google, LinkedIn, and industry-specific directories deliver the best B2B engagement.

Yes, our team specializes in industrial content, product storytelling, and targeted campaign design.

Through analytics dashboards tracking form submissions, call leads, and ROI across campaigns.

Paid campaigns show impact within weeks, while SEO builds long-term organic growth in 3–6 months.